Modern industrial process plants uses Instrument Air as a motive force to various applications like,

1. Operating Final control elements like valves, gates, Power Cylinders, etc.,

2. To operate Various Pneumatic Controllers

3. To operate Pneumatic Tools

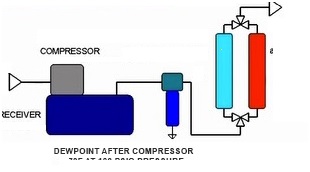

Generally Instrument air is produced by compressing the Atmospheric air with Compressors.

It passes thro Filters , Driers, and receivers, and pneumatic BUS is layed through out the plant, with Moisture trap, strainers, regulators, etc.,

Main Characteristic of the instrument air is it should be DRY and should not contain any Moisture..

Moisture is a critical parameter to be measured, in determining the quality of Instrument air.

Moisture in air will cause Corrosion in Tubes, Errors in measurements, Contaminate the process, Damage the expensive instruments…

How moisture can be measured

Amount of moisture in air can be measured by

1. Humidity

2. Dew Point

3. Vapour Pressure

Most common method is to measure the Dew Point , expressed in Temperature Scale, Should be -40 Deg…

Dewpoint is the temperature at which condensation or dew occurs if a gas is cooled at that Pressure.

Humidity is expressed as relative Humidity, RH, expressed in %.

With the development of technology many sensors are available to measure the Humidity, Dew point, etc…

Typical Instrument Air system

Continuous monitoring, recording of these parameter is generally Practised.